Ultimate Resource for Advanced Automobile Instrument Collection Repair Work Methods

In the realm of modern vehicle maintenance, the complexities of instrument collection fixing stand as a critical aspect of ensuring the optimum functioning of a car (tahoe instrument cluster repair). As innovation advances, so do the complexities of these important parts, necessitating a comprehensive understanding of advanced repair work techniques. With a myriad of possible issues that can develop within instrument collections, having a trustworthy source that uses in-depth advice on troubleshooting and rectifying these obstacles becomes paramount. By checking out the devices needed, common problems experienced, and step-by-step fixing methodologies, one can equip themselves with the understanding required to browse the complex globe of vehicle tool cluster fixing with self-confidence and accuracy.

Value of Advanced Tool Cluster Repair Work

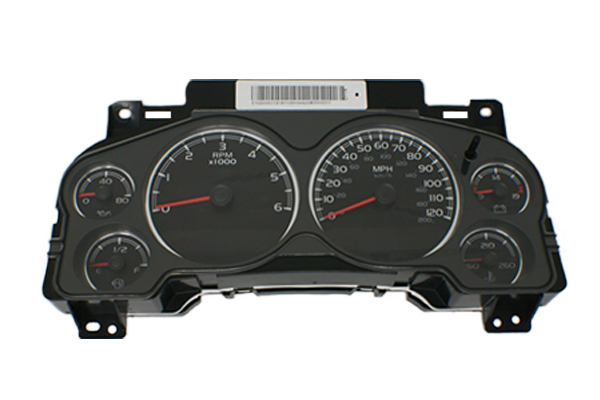

Understanding the value of sophisticated instrument collection repair work is necessary for preserving the capability and accuracy of modern-day lorry systems. The tool collection acts as the center of information for chauffeurs, displaying vital data such as speed, gas levels, engine temperature, and cautioning indicators. With the improvement of technology, tool collections have progressed to integrate intricate electronic screens and electronic components, making fixings a lot more elaborate and specialized.

Proper repair service and maintenance of the tool collection are vital for ensuring the safety and performance of the vehicle. Issues with the instrument collection can bring about unreliable analyses, malfunctions in essential systems, and safety threats on the roadway. Advanced tool collection fixing techniques involve diagnosing electronic faults, altering sensors, and reprogramming software application to bring back optimum efficiency.

Tools and Devices Required

To efficiently address the elaborate repair needs of modern-day lorry instrument collections, a specialized set of tools and devices is crucial. Several of the trick devices needed for sophisticated automobile tool collection repair include accuracy screwdrivers, trim removal tools, soldering equipment, electronic multimeters, and analysis scanners. Accuracy screwdrivers are vital for taking apart the cluster without causing damages. Cut removal devices help in securely spying off panels and bezels. Soldering equipment is needed for fixing busted links or replacing elements. Digital multimeters are made use of to measure voltage, continuity, and resistance throughout analysis treatments. Diagnostic scanners are essential for determining and troubleshooting electronic issues within the instrument cluster. Additionally, having a top quality blowpipe, desoldering pump, and solder cord is essential for executing elaborate soldering work. Proper lights, a magnifying glass, and a clean office are likewise important for guaranteeing accuracy and accuracy throughout repair work. By having these specialized tools and devices on hand, specialists can successfully detect and fix complex problems in automobile tool clusters.

Typical Concerns and Solutions

Several common problems often encountered in auto instrument collections can be efficiently dealt with through targeted remedies. One prevalent issue is damaged assesses, which might result from a malfunctioning stepper go now electric motor. To address this, changing the stepper motor can restore accurate scale analyses. Another usual problem is dark or flickering lights on the tool collection (tahoe instrument cluster repair). This can frequently be credited to a malfunctioning bulb or bad links. By replacing the bulb or ensuring safe and secure links, the lights issue can be conveniently remedied. In addition, a malfunctioning odometer or display screen is a frequent worry. This might be as a result of a defective screen system that needs to be changed to restore correct performance. Recurring power or full failing of the instrument collection may stem from a blown fuse or wiring concern. Checking and replacing the fuse, along with examining the wiring for any kind of damages, can aid deal with these power-related troubles properly. By identifying these typical problems and using the appropriate services, automobile tool collection capability can be brought back successfully.

Step-by-Step Repair Overview

An organized technique to detecting and fixing vehicle instrument collection concerns is necessary for accomplishing precise and reliable outcomes. To begin the repair work procedure, the initial step is to carefully check the instrument collection for any type of visible damages such as burnt-out bulbs, broken displays, or loosened connections. Next, it is important to conduct a diagnostic check making use of specific devices to identify any kind of underlying electronic issues. When the issue locations are determined, the repair service can begin by either replacing malfunctioning elements, fixing harmed wiring, or altering sensing units.

Tips for Preventative Upkeep

After carrying out a complete analysis scan and completing necessary repairs on the vehicle instrument cluster, executing normal preventative maintenance steps is vital to make certain Get More Info lasting functionality and optimal performance of the lorry's necessary assesses and indications. To start, it is necessary to frequently examine the tool cluster for any kind of indications of wear, such as fading screens or malfunctioning lights.

Additionally, updating the software program of the tool collection when essential can make certain compatibility with any brand-new attributes or systems in the lorry. It is additionally advisable to follow the manufacturer's advised upkeep routine and guidelines hop over to these guys for the instrument cluster to keep its long life. By including these preventative upkeep ideas right into your regular vehicle care, you can assist prolong the lifespan and reliability of your vehicle instrument collection.

Verdict

Finally, innovative vehicle tool collection repair work techniques are vital for maintaining the capability of modern-day lorries. By making use of the correct devices and equipment, resolving typical problems, and complying with a step-by-step repair overview, service technicians can successfully identify and fix instrument collection problems. Executing preventative upkeep techniques can help prolong the life-span of the tool cluster and protect against future concerns from developing.

By exploring the tools called for, common problems came across, and detailed repair approaches, one can furnish themselves with the knowledge required to browse the detailed world of auto tool cluster repair work with confidence and accuracy.

A methodical technique to detecting and repairing vehicle tool collection issues is important for accomplishing effective and accurate results. By following this detailed overview thoroughly, auto technicians can effectively repair and detect instrument cluster problems with precision and confidence.

In conclusion, sophisticated vehicle instrument cluster repair techniques are vital for keeping the performance of modern automobiles. By utilizing the proper tools and tools, dealing with typical problems, and following a step-by-step repair service overview, service technicians can properly diagnose and take care of instrument cluster troubles.

Alicia Silverstone Then & Now!

Alicia Silverstone Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!